BLOG ARTICLE

Morristown, TN Industrial HVAC Services: How Manufacturers Can Reduce Downtime With Proactive Maintenance

Industrial HVAC Services for Morristown, TN

Morristown, TN, is home to a growing industrial corridor, automotive suppliers, plastics manufacturers, food processors, logistics companies, metal fabrication shops, and warehousing operations. These facilities all rely on one thing: Industrial HVAC Systems that run safely, efficiently, and without interruption.

Unplanned HVAC downtime doesn’t just inconvenience a building. It can halt production lines, spoil temperature-sensitive materials, reduce employee safety, and cost manufacturers thousands per hour in lost output. This is where proactive industrial HVAC Maintenance makes the difference.

Manufacturing facilities in Morristown, Jefferson City, and the greater Lakeway Region can significantly reduce downtime by implementing a strategic maintenance program designed specifically for industrial equipment, high-volume ventilation, and 24/7 production environments.

Why Industrial HVAC Reliability Matters in Morristown’s Manufacturing Sector

With dozens of industrial employers—including companies in automotive, plastics, metalworking, and distribution—Morristown’s production environment is demanding. Many facilities operate:

- Continuous 24/7 schedules

- High heat-load equipment

- Airborne particulates from machining, welding, plastics, and food processing

- Strict OSHA air quality requirements

- Controlled-temperature production rooms

- Specialized make-up air and ventilation systems

Because of these conditions, industrial HVAC issues escalate quickly and often cause immediate operational disruption.

The Cost of Unplanned Downtime

While numbers vary by industry, national data shows:

- Manufacturing downtime costs $5,000–$20,000+ per minute for some sectors

- Equipment failure drives 42% of all unplanned downtime

- Poor HVAC ventilation contributes to employee fatigue, heat stress, and lost productivity

When HVAC systems fail in a plant environment, the facility often must:

- Shut down high-heat equipment

- Halt temperature-controlled processes

- Send employees home

- Risk OSHA citations for ventilation or air-quality violations

Proactive maintenance drastically lowers these risks.

What Proactive Industrial HVAC Maintenance Includes

Industrial HVAC maintenance is not the same as residential or even standard commercial maintenance. Manufacturing facilities require a customized, high-frequency plan tailored to their equipment load, environmental conditions, and production requirements.

Here’s what a robust industrial maintenance program typically includes:

✅ 1. Quarterly or Monthly Mechanical Inspections

Depending on the facility, maintenance intervals range from monthly to quarterly. These inspections typically include:

- VFD & motor checks

- Airflow and static pressure readings

- Belt, bearing, and pulley inspections

- Refrigerant charge verification

- Coil cleaning and fin straightening

- Heat exchanger and burner inspections (if applicable)

- Damper and actuator calibration

- Leak detection for refrigerant, air, and hydronic systems

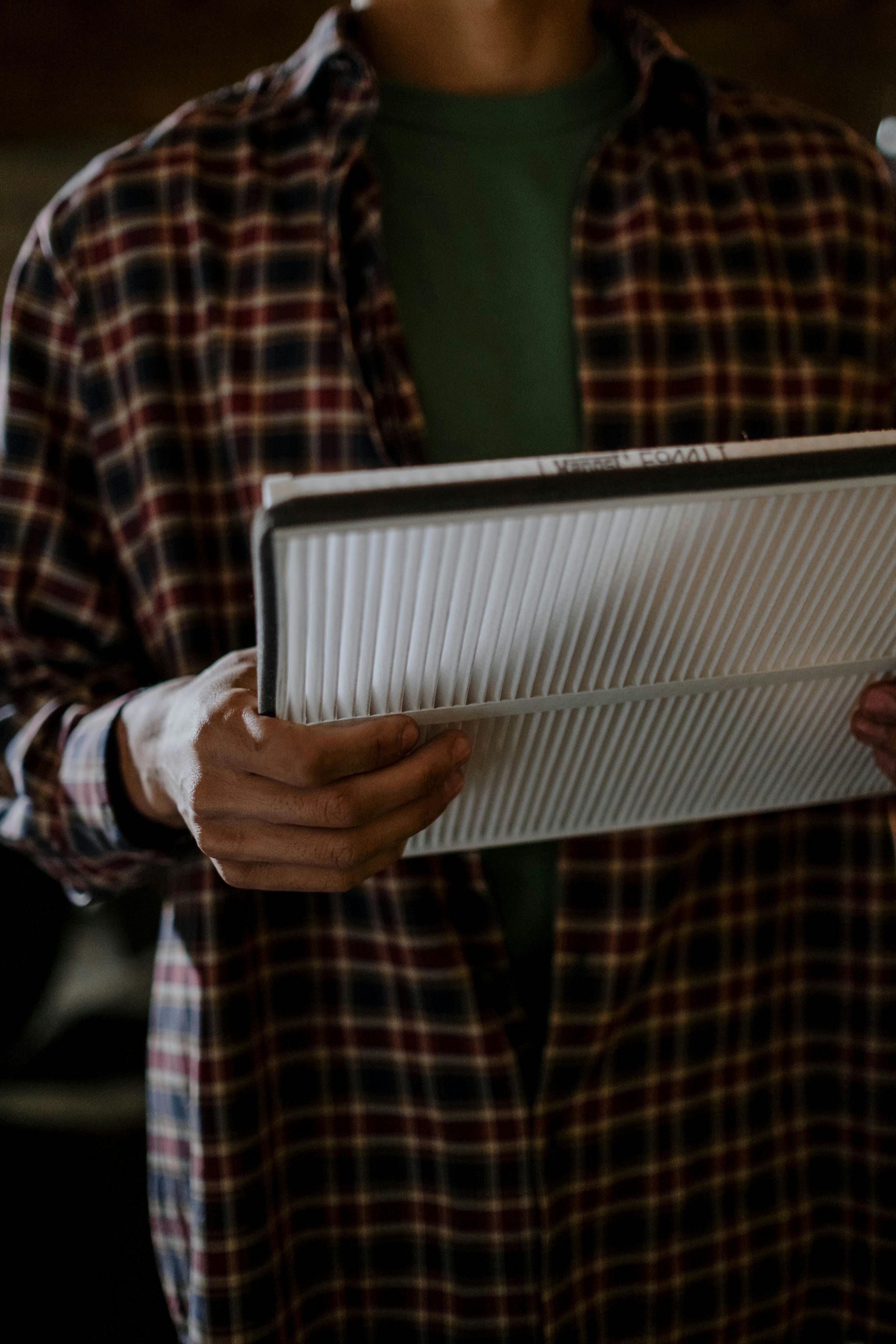

✅ 2. Industrial-Grade Filter & Media Replacement

Industrial particulates clog systems faster than office environments. This includes:

- High-MERV filters

- Bag filters for paint/finishing lines

- Pre-filters for heavy particulate areas

- Carbon filters for odor- or VOC-heavy processes

Filter frequency can be as high as every 30 days in certain industrial zones.

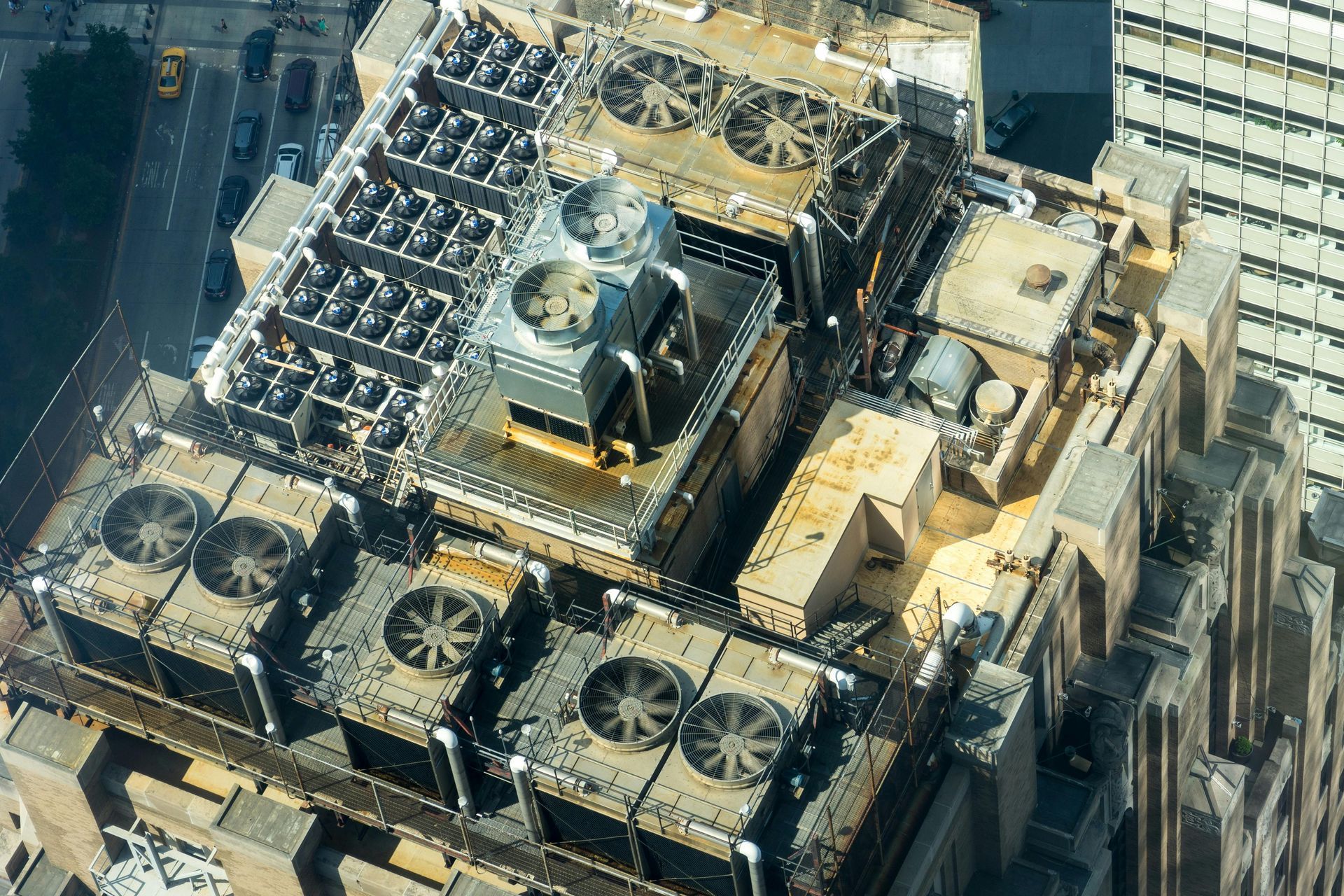

✅ 3. Make-Up Air & Exhaust Balancing

Manufacturers in Morristown commonly use:

- Make-up air units (MAUs)

- Industrial exhaust fans

- Large CFM rooftop systems

- Dehumidification systems

- Heat recovery ventilators

Balancing these systems ensures:

- Proper ventilation exchange rates

- OSHA compliance

- Prevention of negative pressure

- Improved air quality for employees

✅ 4. Predictive Maintenance Technology

Many modern industrial facilities now integrate:

- Vibration analysis

- Motor temperature sensors

- Remote monitoring

- Runtime tracking

- Fault and pressure alerts

- Smart BAS/EMS systems

Predictive technology catches issues before they cause downtime.

✅ 5. Production-Aligned Scheduling

A reliable HVAC partner schedules maintenance around:

- Planned shutdowns

- Shift changes

- Line transitions

- Cleanroom cycles

This eliminates disruptions during active production hours.

Benefits of Proactive HVAC Maintenance for Manufacturers

1. Reduced Unplanned Downtime

The top benefit: predictable, stable uptime. Technicians catch failing motors, blocked coils, degrading capacitors, slipping belts, and airflow issues long before they fail under load.

2. Longer Equipment Life

Industrial HVAC systems are capital equipment. With proper care, plants can avoid premature replacements and extend unit life significantly.

3. Better Air Quality & OSHA Compliance

Facilities in plastics, metals, and chemicals must maintain:

- Minimum ventilation rates

- Acceptable particulate thresholds

- Safe CO/CO₂ levels

- Stable temperature/humidity

Proactive maintenance ensures compliance and safer environments.

4. Energy Savings for Large Facilities

Industrial systems run long hours. Maintenance helps:

- Reduce energy waste

- Keep motors and fans running efficiently

- Maintain consistent airflow

- Reduce load on compressors and MAUs

Savings scale with building size—often thousands per year.

5. Greater Predictability for Plant Managers

Proactive maintenance eliminates HVAC “surprises” and allows managers to budget and plan for:

- Filter changes

- Belt replacements

- Seasonal cleanings

- Minor repairs

- Annual optimization

This reduces emergency calls and improves planning.

Why Manufacturers in Morristown & Jefferson City Choose Phil’s Heating & Air

Phil’s Heating & Air (based in Gray, TN) is uniquely positioned to handle industrial HVAC needs across the Morristown and Jefferson City region. We’re within a 45-minute drive of the Lakeway industrial corridor and already serve major facilities throughout East Tennessee.

Our industrial HVAC capabilities include:

- Preventive & predictive maintenance programs

- Industrial ventilation & make-up air systems

- Rooftop package units (RTUs)

- Split systems, VAV systems, VRF/VRV systems

- Process cooling & temperature control

- Air quality & OSHA ventilation compliance

- Controls integration & automation

- Emergency same-day service

Why facilities trust us:

- Fast dispatch to Morristown, Jefferson City, Talbott, Russellville, White Pine

- Decades of industrial & commercial experience

- OSHA-informed service

- Flexible maintenance plans for 24/7 facilities

- Minimal disruption to production

Ready to Reduce Downtime in Your Facility?

Morristown’s industrial economy is expanding—and HVAC reliability is mission-critical. Proactive maintenance protects your operation, your workers, and your bottom line.

If your industrial facility needs a dependable HVAC partner, reach out today for a customized maintenance assessment.

✅ Industrial HVAC Service

✅ Preventive Maintenance Programs

✅ Commercial & Manufacturing Support

✅ 24/7 Emergency Response

Contact Phil’s Heating & Air to schedule your industrial HVAC evaluation today!

SHARE THIS BLOG POST

MORE HVAC TIPS & TRICKS

Related BLOG Articles